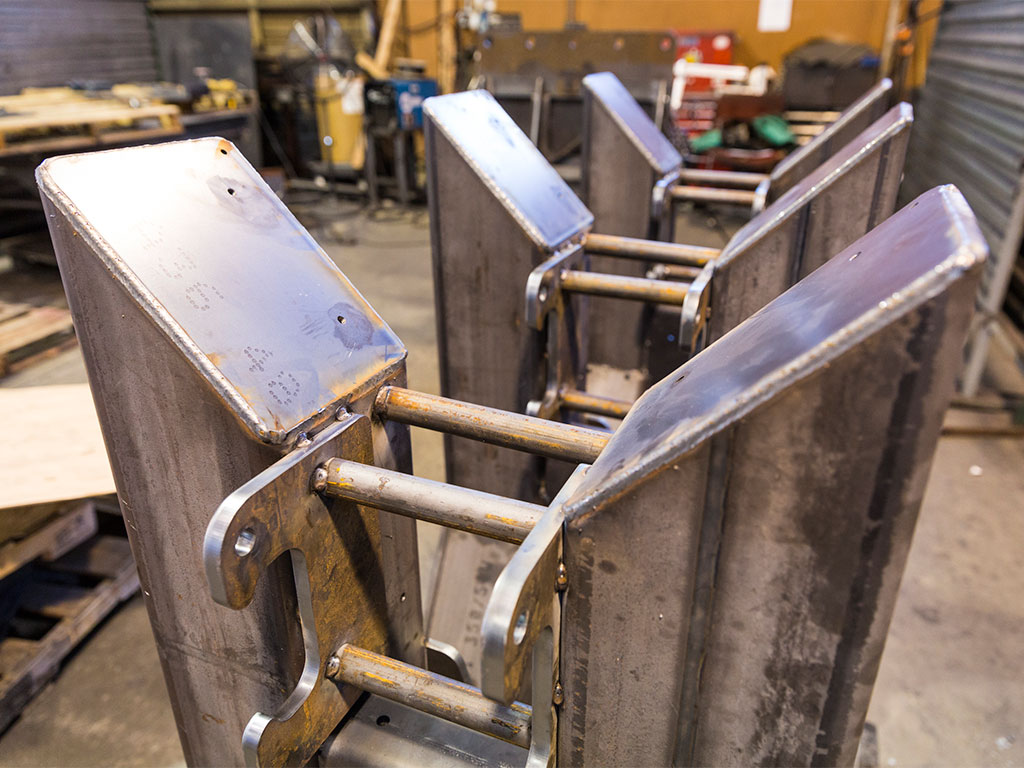

Capital’s 4Kw tube laser cutting system is specifically designed to achieve detailed cuts, complex geometries, and high precision in tube-based materials, including carbon, stainless steel, and aluminum.

Our Mazak FabriGear 3D Tube Laser cutting system can be a real game changer when compared to more traditional manufacturing methods. Laser tube cutting has brought significant process and economic benefits to the fabrication and assembly of mechanical tubing, pipe and structural shapes with a wide range of applications.

Laser tube cutting and profiling offers high precision, ensuring intricate designs are accurately rendered on materials. Its flexibility allows for the handling of various tube profiles at impressive speeds, and its versatility in design supports complex and custom fabrication tasks. The method ensures clean cuts with minimal post-processing, and automated processes that enhance efficiency,