Press Brake Forming

Power, Versatility, and Precision

Our industrial metal forming press brakes offer a remarkable level of force that enables the bending and forming of heavy-duty metal with exceptional accuracy. Industries that require high-quality metal forming to ensure the safety and reliability of their products can rely on Capital Industries’ CNC-controlled press brakes for their versatile capabilities.

Our tandem press brakes exemplify our dedication to delivering exceptional quality and outstanding service in every project we undertake. With our commitment to meeting and exceeding industry standards, including ISO 9001:2000 and ISO/TS 16949:2009, we ensure that our customers receive world-class quality precision and commercial metal forming services.

Get Started

(206) 762-8585

Metal Forming Shapes Our Passions

Metal forming is an integral part of our history and over time has become a core competency of our company. Capital employs a wide range of press brakes with capacities from 90 to 1250 tons and overall bed lengths of 8 to 56 feet. All of our brakes are CNC hydraulic machines for enhanced accuracy, repeatability and productivity.

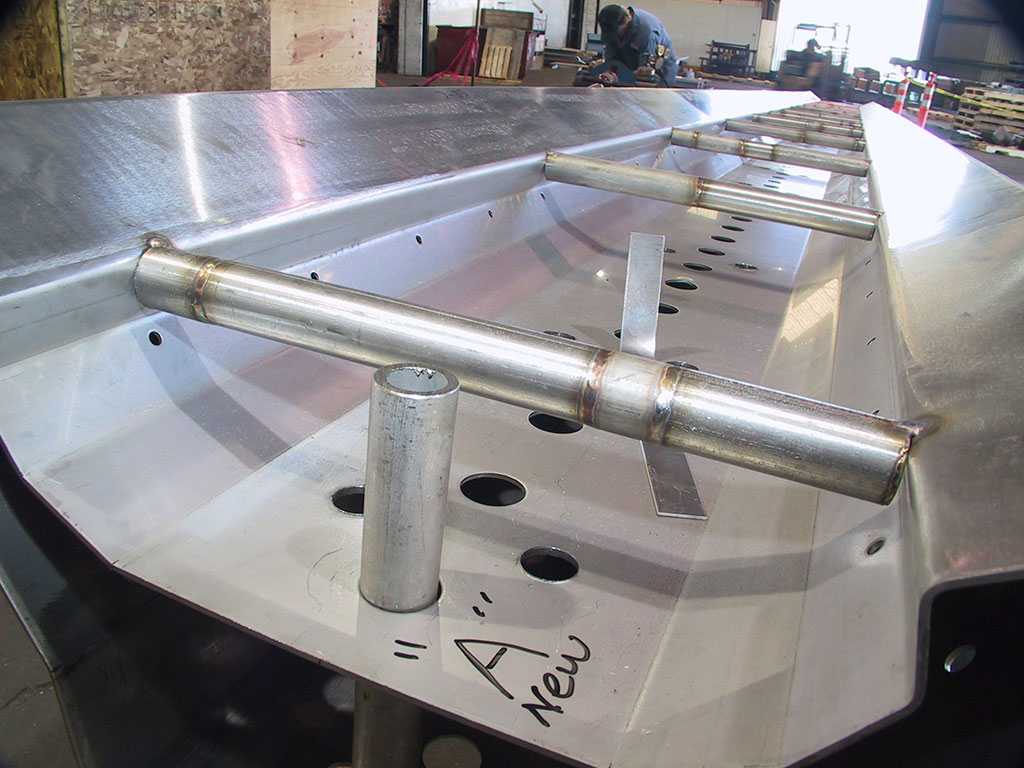

Our tandem 28 foot press brakes give us forming capacity up to 56 feet and 2500 tons, an unusual capability in the Pacific Northwest. For applications that require higher levels of production, we utilize our smaller, high speed press brakes. Our investment in tooling over the years underscores our ability to provide difficult and complex shapes.

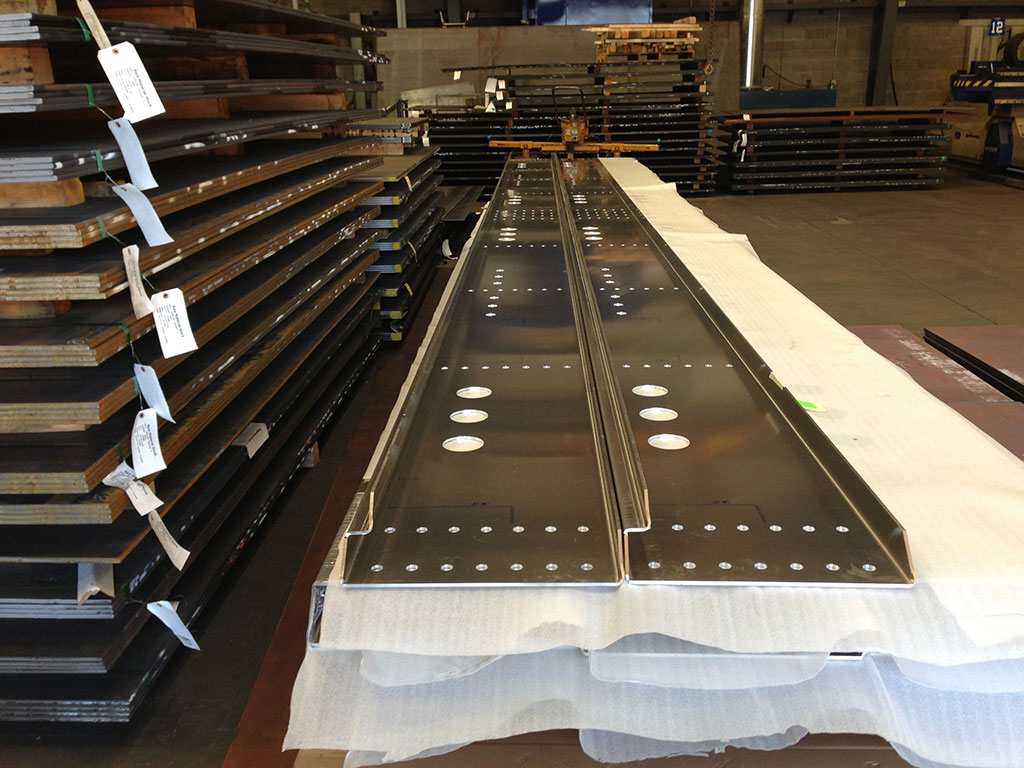

Large Press Brake Forming - 2500 Ton Tandem Press Brakes Forming Up To 56 Feet

These machines offer a remarkable level of force that enables the bending and forming of heavy-duty materials with exceptional accuracy, allowing seamless forming of heavy-duty materials such as steel, stainless steel, and aluminum.

The tandem configuration, where two press brakes work in synchronization enhances versatility. This setup allows for longer workpieces to be bent accurately, expanding the possibilities for crafting large-scale components. The overall bend capacity of up to 56 feet empowers Capital Industries to create extensive shapes without sacrificing precision.

They have laser (10’ x 20’ bed) and forming up to 54’(!).

High Tolerance CNC Precision

High tolerance CNC controls enable streamlined programming and execution of complex bending sequences. Intricate shapes, multiple bends, and intricate geometries can be programmed with ease, reducing setup time and minimizing the need for trial and error.

High tolerance CNC controls play a pivotal role in ensuring that every bend is executed with impeccable accuracy and consistency, offering a range of benefits that significantly impact the quality and reliability of the final product.

Serving a Wide Variety of Industries

We have over 70 years of experience serving industries requiring press brake metal forming including aerospace, construction, marine, and more, where safety, reliability, and precision are a priority.

From shaping massive beams and structural elements, forming substantial metal components to exacting specifications, our goal is to offer broad capabilities, competitive pricing, exceptional quality and outstanding service to each and every customer.