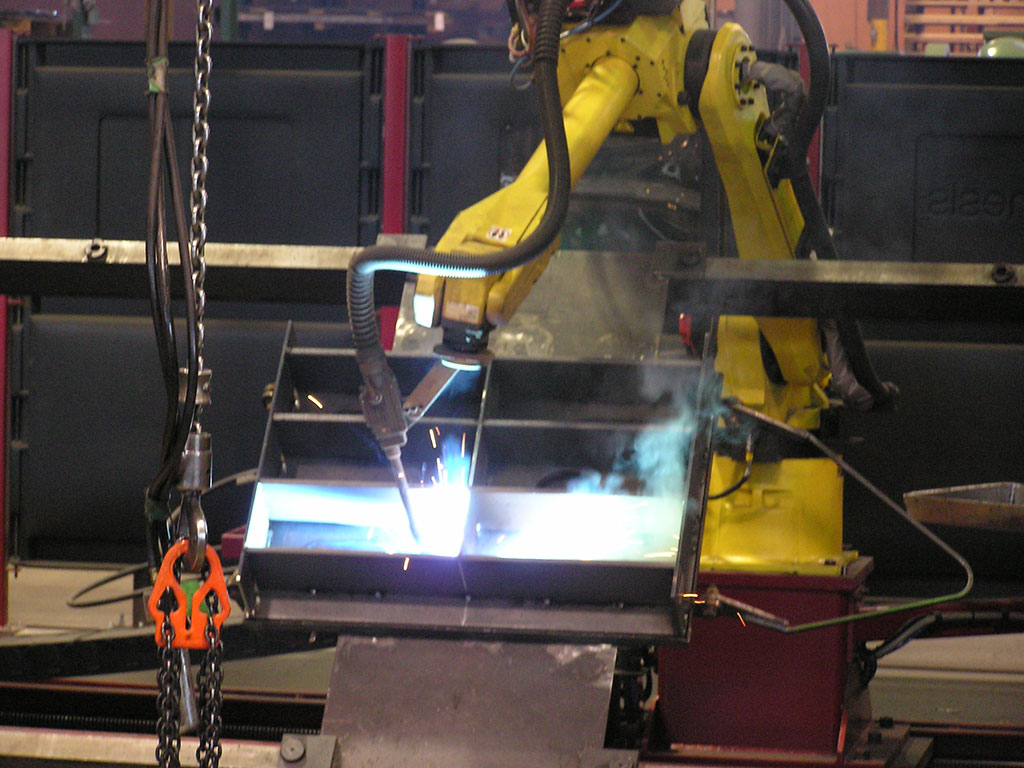

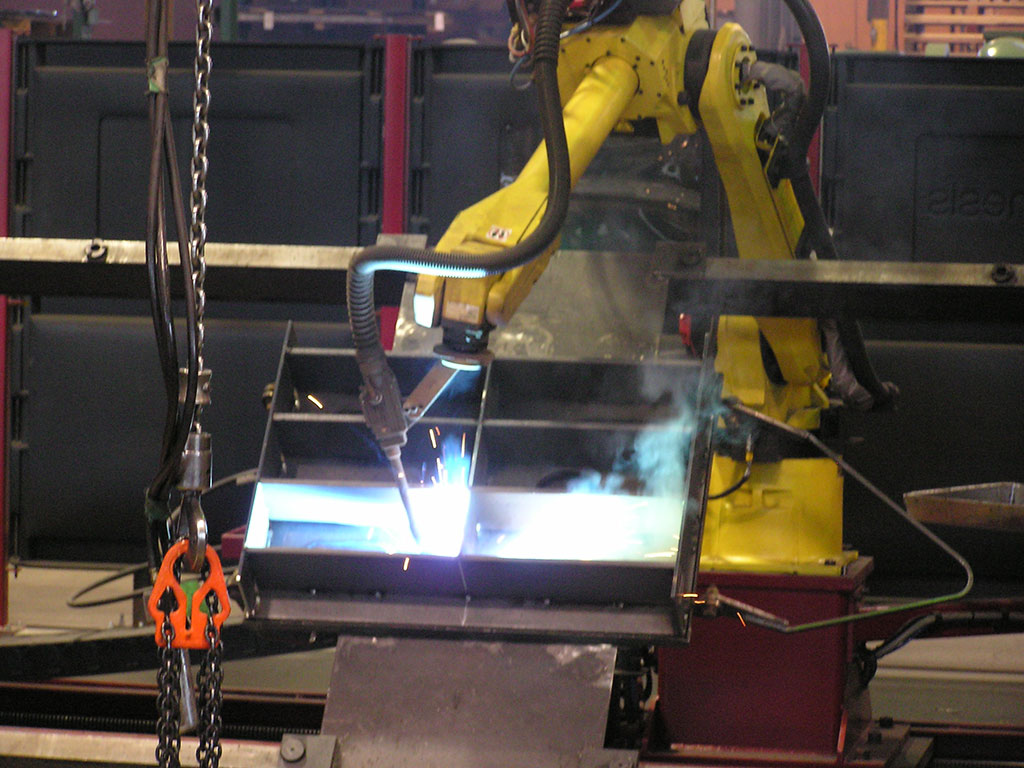

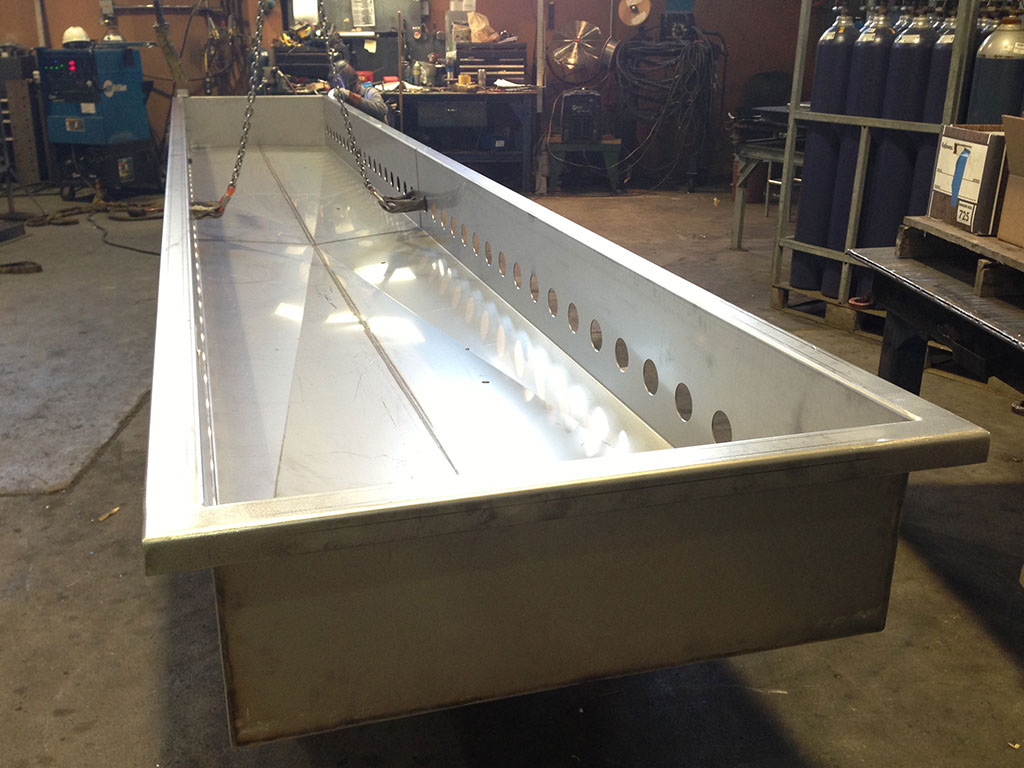

Capital Industries maintains a highly cross function weld team. Our AWS qualified welders are skilled in several weld methods involving a variety of metals. Whether your job requires small part TIG welding or large complex FCAW steel assemblies of 60ft length or more, our team can handle it.

With decades of experience, our team is equipped with diverse welding expertise, ensuring your projects meet the highest industry standards.

- Industry Expertise: Our team of certified welders brings years of experience to the table, ensuring your projects are executed with precision and dedication.

- State-of-the-Art Equipment: We invest in the latest technology and machinery, ensuring that each welding method is performed at its optimal capacity.

- Custom Solutions: Whether you have a one-off project or need large-scale production, we tailor our services to meet your unique requirements.

- Quality Assurance: With rigorous inspection processes in place, we guarantee the quality and integrity of every weld.