Explore our services

At Capital Industries, quality metal fabrication is only one aspect of the value we provide. If consistent, on-time product delivery is vital to your operation, then you know the importance of a dependable supplier. Through collaborative planning and attention to detail, our goal is to ensure that each job results in superior customer satisfaction.

David Taylor, Sr. founded Capital Industries in 1953 with a commitment to traditional business values and a strong belief that we have a moral responsibility to provide quality products at fair prices. His sons, Ron and David Jr. reinforced that duty over their careers and have instilled them in the next generation of Taylors, Bryan and Kyle.

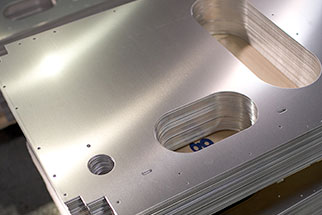

The lineup of equipment on our 3 plus acre shop floor reads like a metal industry equipment catalogue. From 20 foot, 1” shearing capacity to tandem 28’ Cincinnati press brakes to 2 and 5 axis 6,000 watt lasering and 260 amp plasma cutting services, we can accommodate a broad range of opportunities. Our well-seasoned crew and meticulous project planning ensures focus on detail and performance.