Explore our services

At Capital Industries, quality metal fabrication is only one aspect of the value we provide. If consistent, on-time product delivery is vital to your operation, then you know the importance of a dependable supplier. Through collaborative planning and attention to detail, our goal is to ensure that each job results in superior customer satisfaction.

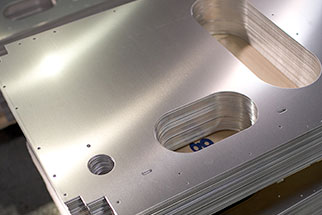

The lineup of equipment on our 3 plus acre shop floor reads like a metal industry equipment catalogue. From 20 foot, 1” shearing capacity to tandem 28’ Cincinnati press brakes to 2 and 5 axis 6,000 watt lasering and 260 amp plasma cutting services, we can accommodate a broad range of opportunities. Our well-seasoned crew and meticulous project planning ensures focus on detail and performance.